Transform your property with a timeless iron fence!

This comprehensive guide walks you through every step of planning, installing, and maintaining your DIY iron fence.

Dive in and start creating the sustainable and elegant fencing solution your space deserves!

Choosing the Right Type of Iron Fence

Selecting the appropriate type of iron fence involves a comprehensive evaluation of several factors, such as:

Styles of Iron Fences

Iron fences are available in various styles, offering visual charm and practical benefits. Modern iron fences focus on clean lines and minimalist aesthetics for those seeking a more contemporary appeal, making them an ideal complement to modern architecture.

Determining the Appropriate Height

The height of an iron fence is determined by its intended purpose. Local regulations and zoning laws should be consulted to ensure compliance with height restrictions.

Material and Finish Considerations

The material and finish of an iron fence play a key role in its durability and maintenance needs. Galvanized iron is an excellent option for areas with high humidity or precipitation, as it offers superior resistance to rust and corrosion.

Fences treated with TGIC (Triglycidyl Isocyanurate) powder coating offer exceptional durability and protection. This advanced coating provides superior surface adhesion, scratch resistance, and shields against environmental wear. Designed for prolonged sun exposure, it helps maintain vibrant colors and prevents issues such as chalking or fading over time.

UV fade resistance ensures the fence retains its sleek, polished appearance even in harsh outdoor conditions. These combined benefits make TGIC-coated fences a reliable, low-maintenance solution for any outdoor setting.

Required Tools for Iron Fence Installation

Installing an iron fence requires comprehensive tools to ensure precision and efficiency. The following list delineates the essential tools required for a successful DIY iron fence installation:

Measuring Tools

Accurate measurement is key for correctly aligning and spacing fence posts and panels. A tape measure is essential for precise spacing. Use a string line to ensure that posts and panels are perfectly vertical and horizontal for optimal alignment.

Digging Equipment

The installation process requires excavating post holes. A post-hole digger or an auger is essential for this task. A power auger may be more efficient for projects involving numerous posts, particularly in dense or rocky soil conditions.

String Line

The primary purpose of a string line is to ensure that all fence posts are aligned in a perfectly straight line. Without it, slight deviations in post placement can lead to misaligned panels and an uneven fence that won’t look professional.

Cutting Tools

Depending on the fence’s specific dimensions and layout, iron panels or posts may need to be cut to size. A metal cutting saw, such as a reciprocating saw with a metal-cutting blade or an angle grinder, is suitable for this purpose.

Fastening Tools

A drill with metal drill bits is required to secure the fence panels to the posts. Additionally, a wrench or socket set is necessary for tightening bolts and screws. It is advisable to use stainless steel or galvanized fasteners to prevent corrosion.

Safety Equipment

Personal protective equipment (PPE) is important to ensure safety during installation. This includes safety glasses to protect against metal shards, gloves to prevent hand injuries, and ear protection when using power tools.

A 2013 study by The University of Iowa Hospitals and Clinics highlights the risks associated with projects such as DIY iron fence installations. The accompanying pie chart on eye injuries treated in the ER illustrates these dangers.

DIY iron fence installation involves cutting, drilling, and grinding, which poses risks to your eyes.

The chart shows that the most common eye injuries include contusions or abrasions (45%) and injuries caused by foreign bodies (32%). These dangers may occur during cutting iron fences, as flying particles, sparks, or debris can easily enter and damage your eyes.

Wearing safety goggles is essential to prevent these risks. Goggles protect against airborne metal debris and sparks, reducing the likelihood of abrasions or particles entering your eyes.

Proper tool handling, ensuring they are in good condition, and using them correctly can help minimize burns (10%) and conjunctivitis (10%), which are also common hazards.

Another important safety measure is a clear and well-lit work area. It reduces the chances of accidents and helps you stay aware of sharp materials, decreasing the already rare risk of puncture injuries (1%) and lacerations (2%).

With safety precautions, you can confidently and successfully install your iron fence while protecting your vision.

Permits and Regulations Should You Be Aware Of

When undertaking a DIY iron fence installation, it is imperative to be cognizant of the various permits and regulations that govern such projects. These include:

Zoning Laws and Property Lines

Local municipalities establish zoning laws to regulate land use and development. These laws can dictate the permissible height, style, and placement of fences.

Property lines must be accurately determined to avoid encroachment on neighboring properties. Encroachment can lead to legal disputes and potential removal of the fence. A professional surveyor can provide precise measurements of property boundaries, which is a prudent step before commencing installation.

Permit Application Process

The process of obtaining a permit typically involves submitting detailed plans of the proposed fence to the local building department.

The review process can vary in duration, often taking a few days to several weeks. To accommodate any potential delays, it is advisable to apply for permits well in advance of the planned installation date.

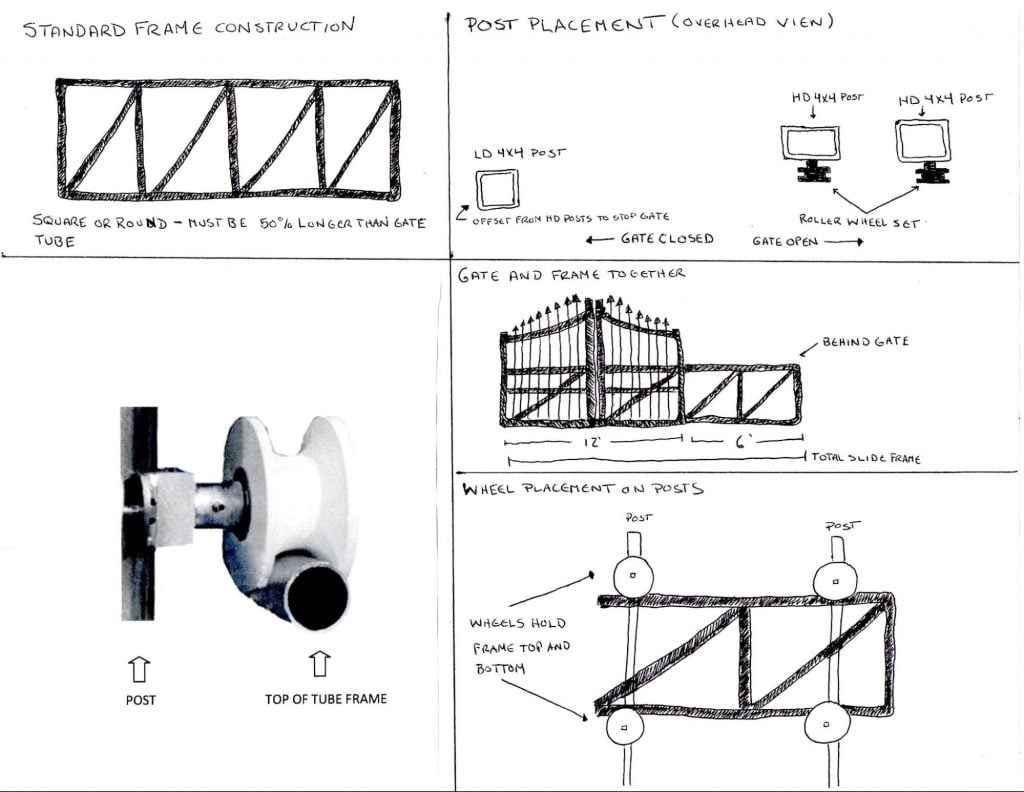

Pre-Installation Planning for Iron Fences

Accurate measurement and marking of the installation area are important steps in successfully installing an iron fence.

The following guidelines provide a systematic approach to measuring and marking the installation area:

Determine the Perimeter

Begin by identifying the boundaries of the area where the fence will be installed. Use a measuring tape to determine the total length of the perimeter. It is advisable to measure twice to ensure accuracy. Record these measurements for reference during the installation process.

Identify Key Points

Mark the locations of key points such as corners, gates, and any changes in direction. These points will serve as reference markers for the placement of posts. Use spray paints to mark these positions clearly.

Calculate Post Spacing

Most wrought iron panels are 96 inches (8 feet) wide. To keep your fence sturdy and aligned, space your posts 96 inches apart for proper panel mounting.

Calculate your post placement by adding the panel width (96 inches) to your post width (typically 2 inches). This gives you an on-center measurement of 98 inches.

Ensure that the spacing is consistent to maintain structural integrity and aesthetic uniformity.

Mark Post Locations

Mark the ground where each post will be installed using the calculated post spacing. A spray paint can be used to ensure the marks are aligned straight. This alignment is essential for maintaining the fence’s visual appeal and structural stability.

Account for Terrain Variations

When marking the installation area, consider any variations in the terrain, such as slopes or uneven ground. Adjust the post locations as necessary to accommodate these variations while maintaining the overall alignment of the fence.

Verify Measurements

Before proceeding with the installation, verify all measurements and markings. This step helps to identify any discrepancies or errors that could affect the installation process. Adjust as needed to ensure the fence is installed according to the planned layout.

Proper Techniques for Digging Post Holes

Adhering to precise measurements and employing appropriate techniques when digging post holes for an iron fence is essential to ensure its structural integrity and longevity.

The following steps outline the procedure for digging post holes and setting posts:

Marking the Locations

Determining post-hole placement begins with running a string line to ensure all posts remain aligned. Use a bright, visible string that can be pulled taut.

Ensure the string represents the outside edge of the posts rather than the center of the fence line for accurate alignment. Position rebar or stakes outside corners to prevent interference while digging post holes, ensuring a straight and precise layout.

Digging the Holes

Excavate the holes using a post-hole digger or an auger. When digging your post holes, start at a marked “on-center” location and dig outward, ensuring the post hole’s center aligns with the string line. Post holes should be dug straight down to avoid issues such as frost heave in freezing conditions.

The diameter of the hole should be approximately three times the post’s thickness. For example, a 2×2 post requires at least a 6-inch-wide hole, while a 4×4 post needs a minimum of 12 inches.

Preparing the Base

Add a layer of gravel to the bottom of each hole. This layer facilitates drainage and prevents water accumulation, which can lead to post-rot or corrosion over time.

Setting the Posts

Position the post in the center of the hole, using a level to ensure it is plumb. Maintaining vertical alignment is essential to prevent the fence structure from leaning or becoming unstable.

Pouring Concrete

Begin by preparing a thick concrete mix with a consistency resembling chunky peanut butter, ensuring it can hold the post upright without additional support.

Start with an end or corner post and place it into the pre-dug hole, orienting any seams inward or outward from your property. Fill the hole halfway with concrete while positioning the post to touch the string line, then pour in more concrete until reaching 2–3 inches below ground level to allow for dirt coverage.

Curing the Concrete

According to the National Precast Concrete Association, an organization that promotes quality precast concrete products, concrete typically takes 28 days to fully cure. However, the curing time can vary due to environmental factors such as temperature and humidity.

As reported by aboutcivil.org in 2017, here is a graph showing how curing temperature affects the compressive strength of concrete over time, expressed as a percentage of its 28-day strength.

According to the chart, concrete cured at higher temperatures, such as 32°C (90°F), gains strength rapidly in the initial days but tends to plateau earlier.

In contrast, concrete cured at lower temperatures, such as 10°C (50°F) or 23°C (73°F) transitioning to 10°C, develops strength more slowly but eventually reaches similar compressive strength levels at later ages.

By 40 to 60 days, the strength of concrete under all temperature conditions converges, showing minimal variation. This highlights that while curing temperature influences the rate of strength gain early on, the final long-term strength remains largely unaffected.

Michigan Concrete Association, an organization focused on supporting the concrete industry, highlights that:

“Strength and durability of concrete increase with age as long as moisture is present and temperatures remain favorable. Lack of curing or poor curing practices can cause a loss of up to 50% of the potential strength and significantly decrease durability.”

Attaching Fence Panels Securely to Posts

Attaching fence panels to posts is a key step in installing an iron fence. It requires precision and adherence to best practices to ensure structural integrity and aesthetic appeal.

The process involves several key considerations and steps, which are outlined below.

Selection of Appropriate Hardware

Use galvanized or stainless steel brackets and screws to prevent corrosion and ensure longevity. Ensure the hardware is designed to work with both the fence panels and posts, considering the thickness and material of each component.

Securing the Panels

Secure the brackets to the posts first with a power drill, ensuring they are firmly attached. Align the panel with the brackets and fasten it using screws, making sure each screw is driven straight to preserve the panel’s integrity.

Verification of Structural Stability

Once each panel is attached, apply gentle pressure to ensure it is securely fastened and shows no movement. Realign any misaligned panels promptly to avoid future structural issues.

Consideration of Environmental Factors

In high-wind areas, reinforce the structure with extra brackets or cross-bracing techniques for added stability. In regions with large temperature fluctuations, use flexible joint materials to accommodate expansion and contraction.

Essential Care Practices for Iron Fences

Maintaining an iron fence is essential to ensuring its longevity and aesthetic appeal. Regular maintenance tasks can be categorized into:

Inspection

Conduct a thorough inspection of your fence. Check for signs of rust, corrosion, or structural damage during the inspection, such as bent or loose panels and posts. Pay special attention to joints and connections, as these areas are more susceptible to wear and may need hardware tightening or replacement.

Cleaning

Regularly clean the fence to remove dirt, debris, and pollutants that may speed up corrosion. Use a mild detergent mixed with water and gently scrub the surface with a soft brush. Ensure all soap residue is rinsed with clean water, as leftover soap can attract dirt and retain moisture. A pressure washer can be effective for stubborn stains or heavy buildup, but use caution to prevent damage to the finish.

Repair

Take care of minor repairs promptly to prevent them from escalating into bigger problems. Tighten loose screws or bolts and replace any damaged hardware as needed. Remove the rust with a wire brush or sandpaper for rusted areas, then apply a rust-inhibitive primer and finish with a suitable paint or protective coating.

Long-Lasting Solutions for Corrosion Prevention

Protecting iron fences from rust and corrosion requires understanding the chemical processes involved and the application of effective preventative measures.

Rust, or iron oxide, develops when iron reacts with oxygen in the presence of moisture. Environmental factors such as humidity, salt, and pollutants accelerate this reaction.

Understanding the impact of these elements is essential for maintaining the fence’s durability. As reported by Corrosion Doctors, the chart below illustrates how pH levels (ranging from 0 to 14) correlate with the corrosion rate of iron (measured in millimeters per year).

Understanding how pH levels influence iron corrosion is essential for maintaining the longevity of iron fences. Iron is more prone to rapid corrosion in acidic environments (low pH), making protective measures such as applied coatings and regular maintenance essential.

Iron exhibits greater stability in neutral and slightly alkaline conditions (pH 4-10), with corrosion rates dropping. This allows fences to last longer with minimal upkeep.

In highly alkaline environments (high pH), corrosion rates remain low, but periodic inspections are still required to ensure the protective layers that naturally develop are intact.

Implementing the following factors is essential for maintaining the integrity and appearance of an iron fence:

Protective Coatings

The galvanization process provides a different approach to corrosion prevention. This method involves coating the iron with a layer of zinc, which acts as a sacrificial anode by corroding in place of the iron. Galvanized iron is particularly effective in environments with high moisture or salt content, offering long-lasting protection.

Alternatively, TGIC (Triglycidyl Isocyanurate) powder coatings offer a durable and aesthetic protective layer for iron surfaces. This polyester-based coating delivers excellent resistance to UV radiation, chemicals, and abrasion, making it ideal for outdoor and industrial applications.

Regular Maintenance

Routine maintenance plays a key role in preventing rust formation and extending the lifespan of iron fences. Start by regularly cleaning the fence with mild soap and water to remove dirt, salt, and other corrosive substances. Avoid harsh chemicals that could damage the protective coatings.

In addition to cleaning, periodic inspections are vital for identifying early signs of rust or damage to the protective layer. Timely detection enables prompt repairs, effectively stopping further deterioration and preserving the fence’s structural integrity.

According to the National Library of Medicine:

“The anaerobic corrosion of iron structures is expensive to repair and can be a safety and environmental concern. It has been known for over 100 years that the presence of anaerobic respiratory microorganisms can accelerate iron corrosion. Multiple studies have suggested that there are sulfate reducers, methanogens, and acetogens that can directly accept electrons from Fe(0) to support sulfate or carbon dioxide reduction.”

Examples of Creative DIY Fencing Projects That Improve Safety and Adaptability

Homeowners are turning to innovative DIY fencing solutions to address safety risks and enhance the functionality of their outdoor spaces.

From building pool enclosures that protect children to modifying hazardous fences into wildlife-friendly designs, these projects showcase the power of thoughtful planning and hands-on effort.

Here are two detailed examples that highlight how DIY fencing can transform spaces while balancing safety, aesthetics, and practicality.

Family Builds DIY Pool Fence to Ensure Safety

A family in Florida sought to improve the safety of their residential pool area after learning about the high risks of accidental drownings, particularly for children under the age of 5. Motivated by the U.S. Consumer Product Safety Commission’s (CPSC) guidelines on pool barriers, they embarked on a DIY project to install a compliant fence system.

The family used the CPSC guidelines as their primary resource to ensure the barrier met safety requirements. They decided to install a 4.5-foot mesh fence with self-closing and self-latching gates. Following the recommendations, they ensured vertical spacing between fence posts did not exceed 1¾ inches to prevent climbing.

The family encountered challenges ensuring the uneven ground did not create gaps under the fence, so they added gravel in problem areas for better stability.

The project was a success, resulting in a layered safety system around the pool. The barrier effectively restricted access, even for the family’s young children, providing peace of mind. The DIY approach saved the family hundreds of dollars compared to hiring contractors, and they felt empowered by contributing to the safety of their home.

By leveraging practical tips from both resources, such as choosing the appropriate fence height, homeowners can create effective barriers that meet safety and aesthetic needs.

The family’s success highlights the importance of planning and adherence to safety practices to achieve fencing that provides lasting peace of mind.

Transforming Hazardous Fences Into Safe, Versatile Solutions

In Lakeway, TX, a pressing concern regarding dangerous iron fences prompted homeowner efforts and city ordinances to ensure local safety. Picket and spiked iron fences posed risks to wildlife, such as deer.

To address this, the city banned spiked and open picket fences in 2019, but homeowners were left to modify existing structures to comply with safety standards.

One particular example highlighted a Lakeway resident, Hamil Cooper, who undertook DIY efforts to make his fence safe. Using a Sawzall, he removed the protruding spikes from his metal fence and plugged the exposed holes using rubber caps ordered online. This cost-effective solution prevented further dangers to wildlife, showcasing how handy homeowners can take proactive measures.

These modifications have been widely successful for various applications beyond the home perimeter. Iron fences can double as pool enclosures with adjustments such as flat-topped panels.

By combining elegant design with safety measures, these DIY approaches offer homeowners versatile, reliable fencing solutions tailored to their unique needs.

Leveling Techniques for Sloped Fence Installation

When installing an iron fence on uneven ground or slopes, it is important to employ techniques that ensure aesthetic appeal and structural integrity.

The primary challenge lies in maintaining a consistent fence height while accommodating the natural variations in terrain. This can be achieved through two the following methods:

Steping Method

For a yard with a mild slope, you can “stair-step” the fence panels by installing each panel at a slightly different height on its posts to create a series of steps that follow the grade. This method ensures a consistent panel-to-ground clearance while maintaining a uniform top profile.

To implement this method, measure the slope’s gradient and determine the height difference between adjacent posts. Adjust the post heights accordingly to maintain a uniform appearance.

Ensure that each post is securely set in concrete to prevent movement, which can be more pronounced on sloped terrain.

Backfill Method

For steeper slopes, shorten panels by cutting them into smaller sections and adding extra posts to keep gaps at the bottom of the fence manageable.

When placing your posts, remember to dig them deeper on the higher side of the slope so they stay tall enough for proper support. The standard panel width is 96 inches, but when you trim a panel, leave at least 1.5 inches of rail on each end so the brackets fit securely.

To finish, you can backfill with soil or stones under the panels to close gaps if needed, just make sure not to block drainage. With careful adjustments, you’ll have a level-looking iron fence that hugs the slope.

Clearing Pathways for Smooth Iron Fence Installation

When installing an iron fence, encountering natural obstacles such as trees or rocks is a common challenge that requires strategic planning and execution.

Addressing the following obstacles effectively ensures the fence’s structural integrity and aesthetic appeal:

Trees and Roots

Start by thoroughly assessing the tree’s root system, as roots often extend well beyond the visible canopy. Disturbing these roots can harm the tree and compromise the fence’s stability. To mitigate these risks, plan the fence line strategically to minimize root disturbance. This may require adjusting the layout to curve around the tree or adopting alternative post-placement methods.

One effective strategy is using offset post placement, where fence posts are positioned safely from the tree roots to prevent cutting through major root systems.

Additionally, consider using adjustable brackets or flexible connectors to accommodate the tree’s natural growth and movement over time, ensuring the fence remains functional and tree-friendly.

Rocks and Rocky Soil

Start by identifying the size and location of rocks along the intended fence line through visual inspection or, if necessary, subsurface probing. Determining whether the rocks are surface-level or embedded in the soil is essential, as this will dictate the most effective installation method.

Repositioning the fence line to bypass the obstacle may be a viable solution for surface-level rocks. If repositioning is not feasible, rock drilling equipment can be employed to create suitable holes for post-placement. For embedded rocks, consider using specialized tools such as rock augers or pneumatic drills to penetrate the rock and secure the posts.

Alternatively, concrete footings can anchor posts above the rock surface without sacrificing stability. In addition, corrosion-resistant materials and coatings for posts and brackets should be used to prevent long-term degradation in rocky or root-filled environments.

Finally, reinforce posts with additional bracing or support structures to address potential instability caused by uneven terrain or root movement, ensuring the fence remains durable and strong.

Simplify Your DIY Fence Installation

Installing an iron fence can be rewarding, but preparation and precision are key to success. You can create a durable and visually appealing fence by choosing the right style, height, and materials, planning your layout carefully, and using the proper tools and techniques.

Safety is paramount; use protective gear and follow best practices to prevent injuries while working with iron. Regular maintenance ensures your fence remains attractive and resilient against rust and environmental elements.

Begin your project confidently and transform your space with a sturdy, elegant iron fence!

References

- Chorioretinitis Sclopetaria: A Systems Based Approach to Eye Injury Prevention. (n.d.). The University of Iowa Hospitals and Clinics. https://webeye.ophth.uiowa.edu/eyeforum/cases/175-Sclopetaria-Chorioretinitis.htm#gsc.tab=0

- How Long to Cure Concrete and Effects of Curing. (n.d.). aboutcivil.org. https://www.aboutcivil.org/concrete-curing-methods-effects-requirements.html

- (n.d.). Corrosion Doctors. https://www.corrosion-doctors.org/Forms-crevice/iron-corrosionX.htm

- Safety Barrier Guidelines for Residential Pools – Preventing Child Drownings – CPSC Publication 362. (n.d.). Pool Safely. Retrieved January 15, 2025, from https://www.poolsafely.gov/wp-content/uploads/2016/04/Safety-Barrier-Guidelines-for-Residential-Pools.pdf

- Safe Fencing. (n.d.). Lakeway Texas. https://www.lakeway-tx.gov/1778/Safe-Fencing

Free Shipping over $5,000

Free Shipping over $5,000

15 Years in Business

15 Years in Business

18mo No Interest Financing

18mo No Interest Financing